Nagoya Kuromontsuki-zome

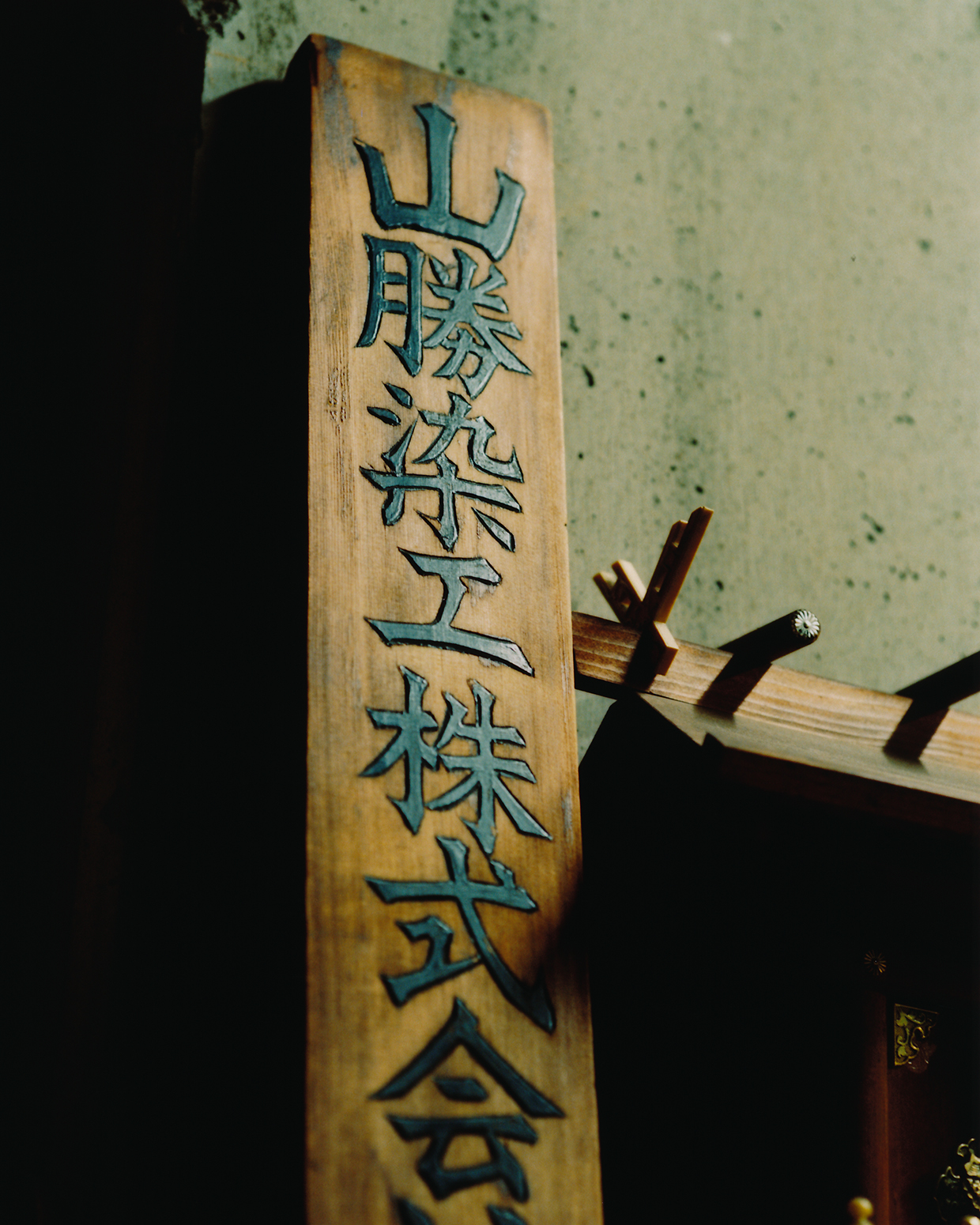

Yamakatsu Dyeing, specializing in Nagoya black crested dyeing, was established in 1919. Yamakatsu Dyeing, a company specializing in Nagoya black crested dyeing, was founded in 1919. We have been in business for 103 years this year under the corporate philosophy of “keeping the traditional black while never forgetting to change. This year marks the 103rd anniversary of the company’s founding. We interviewed Mr. Nakamura, who is making various efforts to meet modern needs in order to preserve Japanese kimono culture through Nagoya Kuromonzuke dyeing, despite the crisis facing the traditional industry due to declining demand.

This year marks the 103rd anniversary of Yamakatsu Dyeing Co. You and your brother are currently running the company, is that correct?

The company was founded by my great-grandfather, and my younger brother is the fourth generation. My brother is in charge of production and I am in charge of sales. I had no intention of taking over the company, I joined once, but I didn’t get along with my father, so I quit. After that, my younger brother took over the company and worked with my father. I was doing something else, but my father died. So I thought I had no choice but to come back. I am more attached to my home than to the company. I thought I shouldn’t lose it.

When I came back, I thought, “This is really bad. You often hear that traditional industries are in trouble. But when you become a participant, you realize how bad it is. I had already gone beyond what you might think of as “bad. I thought that in order to turn the situation around, I would have to go even faster than the speed at which other people were moving, so I did what I had to do for about 10 years.

How many craftsmen are currently working at Yamakatsu Dyeing Co.

Now there are two of us: the factory manager and our younger brother. When I was a child, there were five or six of us. There was my grandfather, my father, his brother, and the craftsmen.

First of all, please tell us about Nagoya kuromonzuke dyeing and what traditional techniques you use to make your products.

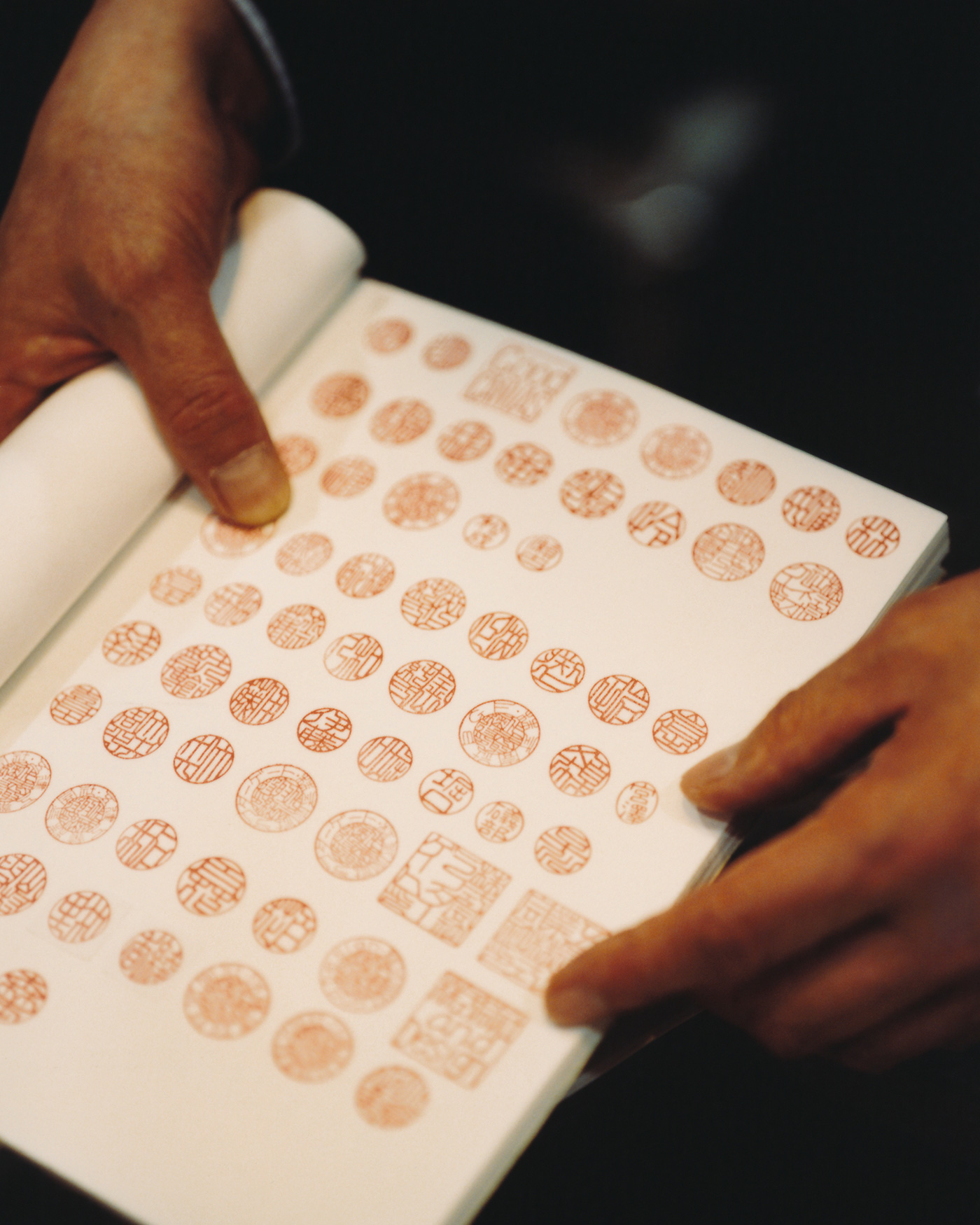

Nagoya Kuromonzuke Dyeing” is a dyeing process used to make black montsuki. Kuro-montsuke itself dates from the late Edo period, and was originally used to dye banners. In short, one of our dyeing techniques is to dye a “crest” by leaving the original fabric color white within the black dyeing.

Solid dyeing is the ultimate in dyeing. It is actually very difficult to dye a solid color without any irregularities. And it is quite a feat to remove the white and make the ultimate black. So, from the point of view of dyeing professionals, the fact that it is dyed black is in itself amazing. They say that such a color cannot be obtained.

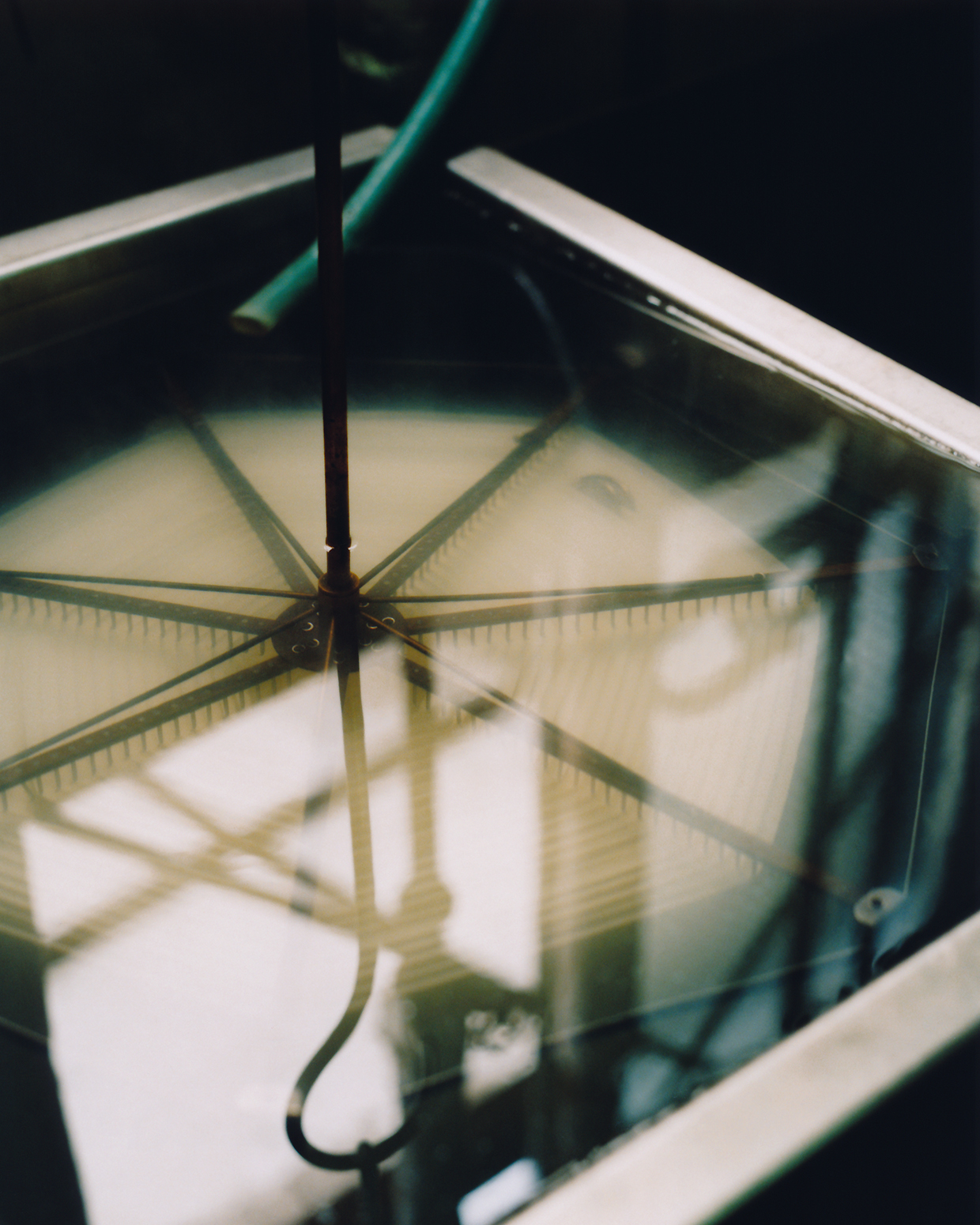

Another technique unique to Nagoya is to attach a wire mesh. By attaching a wire mesh, it can be kept in the dye for a long time. Another technique is Japanese paper. The fabric is sandwiched between paper patterns from the top and bottom, and a wire mesh is placed on top of the paper patterns and fastened with thread. When it contains water, the Japanese paper part expands and presses more against the pattern paper, which is then pressed. The katagami does not shift.

The technique of katagami has been around since the 1800s. Originally, it was held down by something hard like wood, but it gradually changed to wire mesh. But there are no more craftsmen who make this wire mesh. When our traditional industry declines, the first thing that will disappear are the toolmakers. This is because one tool shop can only exist with 10 or 20 dyeing shops like ours, so one tool shop cannot exist by itself. And a traditional industry that is unique to Nagoya can only be made in that region.