Ando Cloisonne was founded in 1880, so it has a history of more than 140 years. Cloisonne enamel art requires a division of labor between specialized craftsmen for each process, and it seems that every process requires a very high level of skill.

The story is a bit long, but first of all, cloisonne enamel ware has a long history of being produced under the division of labor. I think that efficiency and rationality were also taken into consideration, and it takes time to acquire specialized skills in each process, so the division of labor was established in this way. However, that was when cloisonne enamel ware was widely used in the world to some extent. As the demand for cloisonne enamel ware decreased, it became difficult to maintain the division of labor.

So today, each craftsman has his own specialty, for example, one is good at glazing, one is good at applying silver wire, and one is good at polishing, while at the same time being able to do other work. So, in the course of our work, bottlenecks in the process will appear, and we will gather craftsmen there to solve those bottlenecks.

Another thing about having craftsmen on hand is that we are more grateful if we outsource. We can just put in what we need, when we need it, as long as we need it. However, demand itself is decreasing, and the companies that we used to outsource to are now going out of business. The outsourcing companies are usually run by one or two craftsmen, which is fine as long as they are still in good health, but there is a problem of lack of successors.

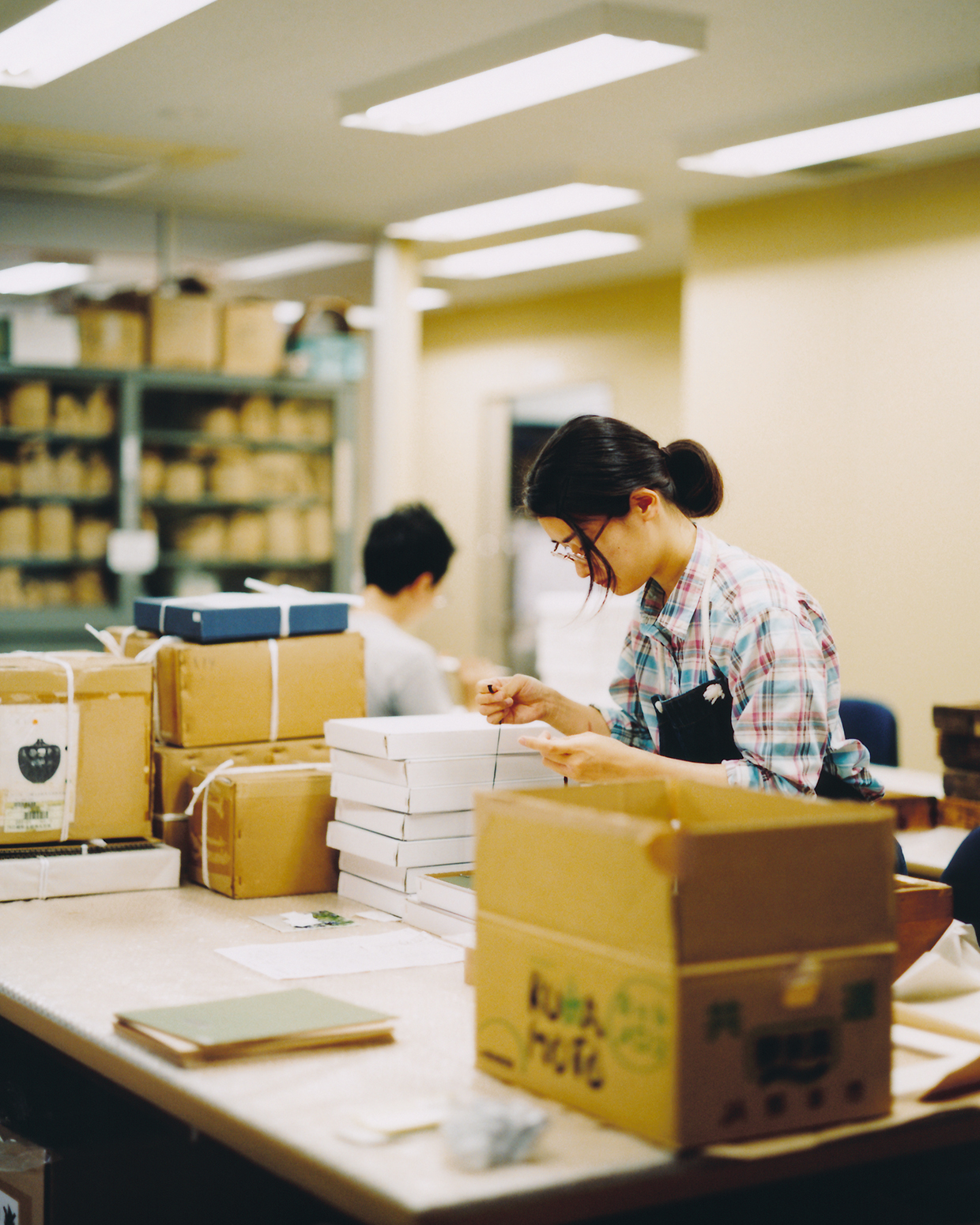

As for what we did, the first thing we did on the hardware side was to relocate the factory and build a factory that can handle all processes. The second is the issue of human resources. The people who have the skills are getting old, and we need to be able to pass them on to the next generation.

For example, a company with plating technology in Niigata was going out of business, which was very troubling for us. But the craftsman in Niigata said, “Mr. President, if there is someone who can take over this technology, I will go to Nagoya as well. The young people are now passing on the skills to the next generation.

The glazing company in Kawasaki was also a small to medium-sized company. The craftsmen from Kawasaki are now coming to Nagoya because of the difficult situation in Corona. So, this factory is in a transitional stage where craftsmen of a certain age are transferring their skills to the next generation.

When I visited the Ando Cloisonne factory, I was surprised to see so many young women, which was different from my initial image of traditional industry.

Everyone is surprised. We are actively hiring new craftsmen. This is something we have been doing for more than 10 years. I am often asked if young people are not interested in traditional crafts, but the opposite is actually true. Whenever we are looking for engineers, we have a number of young people who have come to our door and joined our company. That is why we are very cheerful when it comes to hiring. Well, we built this factory because we have children who actively want to inherit these skills.

How many artisans are currently working at Ando Cloisonne?

Including design, we have about 15 people now. The oldest is over 70 years old, the rest are in their 60s and 50s, and the rest are in their 20s to 40s. Recently, the number of young people has increased to more than half of the total.